Ceramic Printing

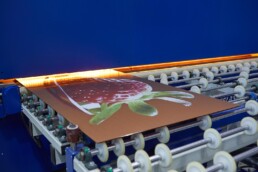

Starting from April 2020, TRANSPARENT DESIGN benefits from VITRO JET FS8 digital printing machine, TECGLASS SPAIN, which is the leader in the field – with JUMBO size 6000×3000 MM, the only machine in the country in terms of size and technology.

- 16 printing heads

- 16.000 nozzles

- Maximal resolution: 1440 dpi

VITRO JET can reproduce on glass any graphical design, templates, or photos with ceramic inks. This is equipped with an automatic drying system, permitting glass drying simultaneously with the printing, decreasing the manufacturing time. This technology, unique on the market of ceramic digital printing, significantly decreases the risk of dust contamination of glass, providing a quality ending result.

VITRO JET has an advanced technology of the VARIABLE DROP SIZE (VDS) printing heads, enabling the machine to adapt the ink flow (7 levels) according to the high opacity level (typical for the templates) or by the image high resolution.

Unique technology on ceramic digital printing market

Custom design

VITRO JET can reproduce on glass any graphical design, templates, or photos with ceramic inks.

Reduced time

This is equipped with an automatic drying system, permitting glass drying simultaneously with the printing, decreasing the manufacturing time.

High quality

This technology, unique on the market of ceramic digital printing, significantly decreases the risk of dust contamination of glass, providing a quality ending result

Such printed glass will be immediately introduced in the toughening furnace and ceramic inks get fused into the glass surface, benefitting from high resistance to scratches, UV rays or temperature differences.More, ceramic printed glass is a safe product, resistant to shattering. Due to these properties, the ceramic printed glass can be used for indoor design, for outdoor applications on buildings facades or for assembly into IG- units.

Applications

Ceramic digital printing has a large range of uses, being used for either monolithic glass or laminated glass applications.

Being a tempered glass, UV resistant, ceramic printed glass can be used for:

Advantages

The advantages of digital ceramic printing are obvious. Any type of high-resolution images can be reproduced, even in large sizes. The image is divided into several glass panels of different sizes and forms, thus covering any size or space.